SARIA Global Newsletter May 2023

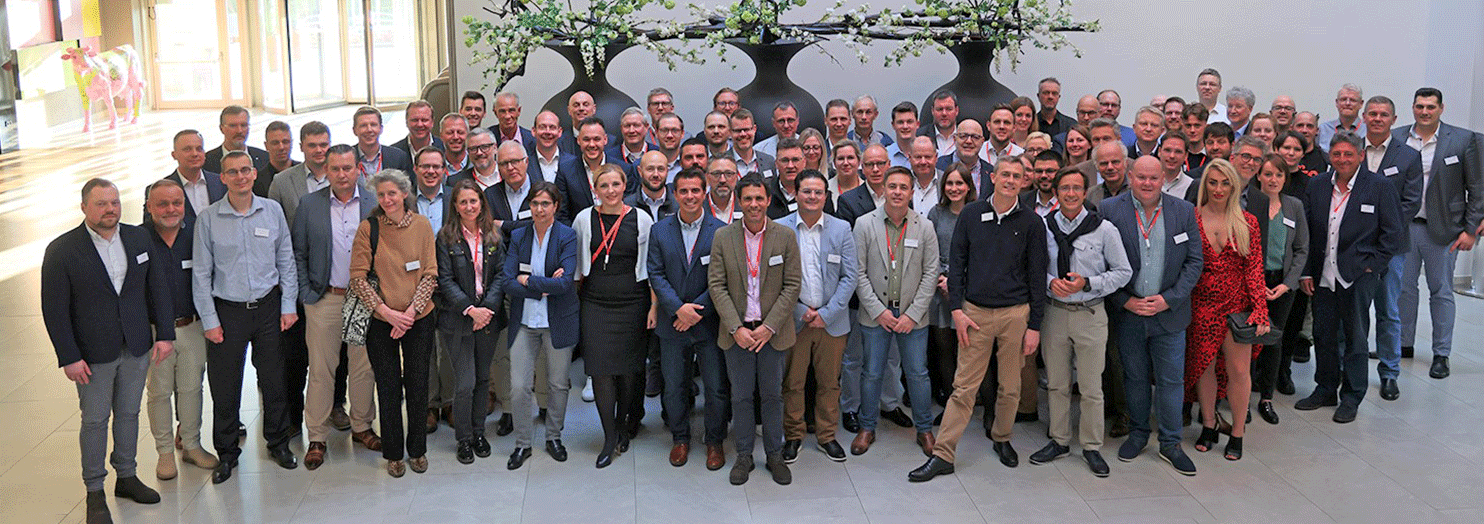

O2P: Management Meeting 2023

From April 19 to 21, managers from O2P division met in Dusseldorf (Germany) to discuss a new positioning of brands and how to use digitalization to improve the business activities.

At the first Europe-wide O2P meeting, the representatives from Spain, France, Poland, Germany, UK, Austria and the Netherlands were welcomed by the responsible SARIA Executive Board members Nicolas Rottmann and Franz-Bernhard Thier, as well as Dr Martin Rethmann, member of SARIA’s Supervisory Board.

In addition to presenting ideas for new brand presences, the participants (ecoMotion, GERLICHER, ReFood, SARVAL Fischermanns) worked out concepts in workshops on how digitization can be used to improve the potential of their own business activities. These ideas will be used by the responsible managers to draw up concrete operational plans for delivering real solutions.

The meeting in Düsseldorf was an excellent opportunity to exchange ideas and make contacts with many different stakeholders from the various countries and business units, thereby improving cross-country collaboration at business and divisional level. This event was a huge success for the potential start of an annual event series.

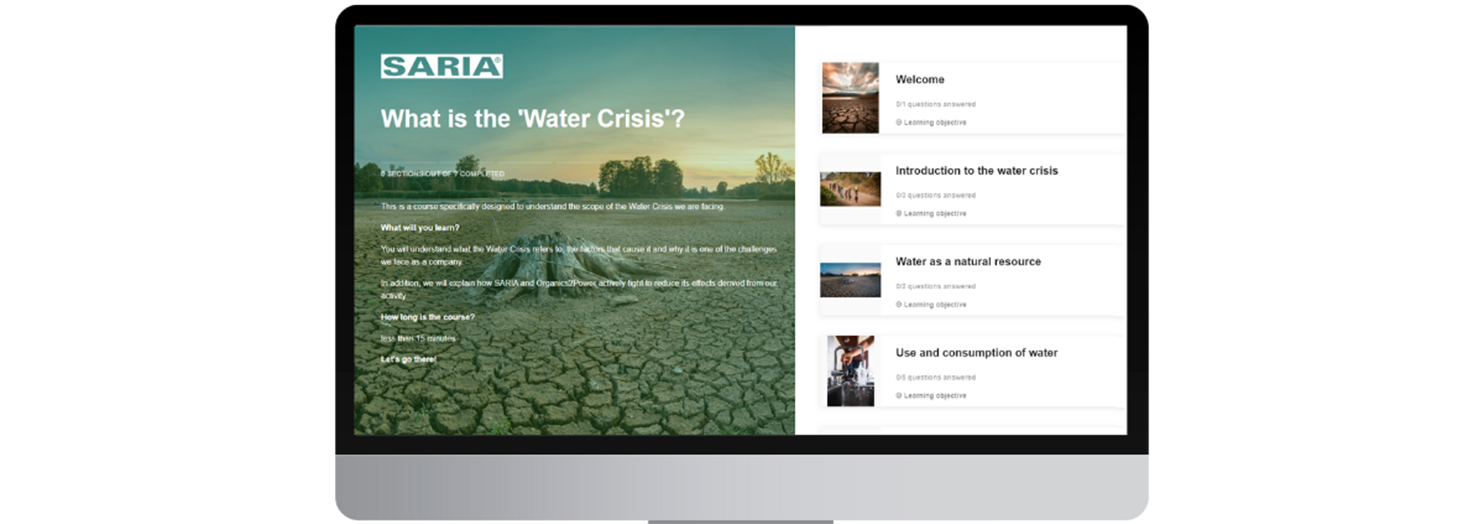

O2P: sustainability e-learning platform

O2P raises awareness of sustainability by implementing an e-learning platform. It started with a pilot course in Spain.

Sustainability is in the DNA of the division O2P because the business model and values within are deeply rooted in sustainability.

But what is sustainability?

To bring this terminology even closer to employees, the Spanish Sustainability and Communications team has initiated a pilot project with the aim of raising awareness of sustainability among employees, helping them to understand the impacts of their activities on the environment and to work together as a team to achieve sustainable goals.

The project was implemented in Spain using an e-learning platform. In a 15 minutes course, employees learn about sustainability concepts, measures and projects. This platform is easy to use and accessible to all employees, even those without access to the computer – like drivers and production colleagues.

The first courses took such important topics as:

- The water crisis with related impacts, and how SecAnim in particular is water efficient thanks to water treatment plants.

- The introduction to sustainability with the presentation of the Sustainable Development Goals (SDGs), as well as O2P Division’s own objectives with regard to a sustainability strategy.

The e-learning platform also provides detailed information on the division’s current sustainable projects. Employees can learn about initiatives such as waste reduction, energy efficiency and the use of renewable energy. Practical tips are also provided on how employees themselves can help make their work more sustainable.

The project is proving to be a great success, as the interest is very high. There have already been 180 interested people signed up for the courses so far, and in less than a month a total of more than 65 hours of classes have been held.

In the coming months, the project will also be implemented in France and Poland to promote awareness and information on sustainability among all employees.

O2P: new design on the ReFood websites

since the beginning of April, ReFood websites in France, Spain, Poland, Germany and the Netherlands are looking very similar – this is a powerful example of synergy for brand identity.

It’s common knowledge that strong brands have a coherent visual identity. No matter where you are it is easy to recognize the “Coca-Cola” red logo. Of course, this is an example from consumer goods, but it works exactly the same in the B2B environment. Combining synergies in the corporate appearance helps to build a consistent brand image that ensures recognition and strengthens the position on the market, even if the business activities remain local. Sales teams can effectively promote with a strong brand that looks similar in other countries, and it helps the communications and marketing team collaborate across countries and share proven promotional materials as a result.

Based on the French design, ReFood Poland and Spain wanted the same look for their website. Since the German and Dutch websites also needed to be redesigned, it made sense to take a collaborative approach. Some accompanying circumstances have promoted the fast process of the change: the website has been moved to a new server, the needs of the sales force and the preparation of a new brand positioning for the ReFood brand in Spain, France and Poland.

The entire process of converting the ReFood websites was driven by the responsible teams within the O2P division and SARIA Group Communications. The new websites are powered by SARIA servers, ensuring security and rapid customization. Future plans include taking the customer perspective and using best practices from other countries – such as the ReFood sustainability calculator from the Daka ReFood website, which is also to be included on the ReFood websites in Spain and Poland.

Stay tuned and check out the new websites: ReFood Spain, ReFood Poland, ReFood Netherlands, ReFood Germany.

O2P: commitment to decarbonization and sustainable mobility

In mid-May, ReFood Spain became the first company to test a fully electric truck at the ReFood plant in Llerona (Spain).

This is an important contribution against climate change and a response to customer expectations.

As part of the commitment to decarbonization, the logistics of all our businesses play a key role in reducing our environmental impact and carbon footprint. This involves the use of various tools such as route optimization, eco-efficient driving, as well as the use of alternative fuels to diesel.

Currently, several European cities like Barcelona, Paris or Madrid are implementing access restrictions to improve quality of life and reduce CO2 emissions. This, along with increased demands from the customers, has posed a challenge for truck manufacturers, who have had to innovate for vehicle efficiency (Euro 5-6) and develop new technologies such as electric vehicles, fuel cells, and synthetic fuels.

In this context, collaboration with long-standing partners of the SARIA Group, such as Mercedes, is particularly important in order to jointly study different mobility models and determine which one best meets future needs and, above all, offers maximum benefits to customers. During the week of May 8-12, 2023, an all-electric 27-tonne Mercedes eActros was used in Llerone, one of ReFood’s main sites in Spain. With a customized route plan, experienced drivers, and a range of 300 km, the vehicle efficiently completed various routes and served specific customers.

The data collected by Mercedes through its telematics system will allow ReFood to evaluate the viability of this model. At the same time, ReFood is organizing further trials in other countries within the O2P division to gain comprehensive experience.

One thing is certain: ReFood and the O2P division will continue to work on reducing its own carbon footprint, and in doing so, alternative mobility solutions to fossil diesel, among others, will be the answer to current and future environmental challenges. In this context, partnerships with companies that want to tread the path of sustainability together with us will be particularly important.

ReFood Germany: Biodiesel production in Sternberg now part of the portfolio

As one of the pioneers of the European biodiesel industry ‘SARIA Biodiesel GmbH’ in Malchin (Germany)- now ecoMotion – developed a process at the end of the 1990s to produce biodiesel from animal fats.

This biodiesel was to be used primarily for SARIA’s own fleet of vehicles but also for its sister company, REMONDIS. You can read more about the history of ecoMotion in SARIAnews 2022. Due to the legal biodiesel quota, today it is mainly the European mineral oil industry that is a customer of ecoMotion.

In 2006, the Sternberg (Germany) site was put into operation. This ecoMotion site is the only one that produced biodiesel not from animal fat, but on the basis of rapeseed and rapeseed oil. However, since 2018, used cooking oil (UCO) have also been processed into biodiesel at Sternberg, which now contributes to over 80% of biodiesel production on site. Originally used as a pre-process for rapeseed biodiesel production, an oil mill is still operating at the site today. Rapeseed oil and rapeseed protein are produced independently of the company’s own biodiesel production.

In addition, RVM Logistik GmbH has been part of the Sternberg site since 2006. At the beginning, this was just a transport company for ecoMotion’s plant traffic, but in recent years it has been consistently developed into an independent and autonomous haulage company for tankers. In addition to raw and additive material supply and logistics of ecoMotion biodiesel, the company also provides cargo logistics for other customers.

In September 2022, it was announced that SARIA and Total Energies will produce sustainable aviation fuel (SAF) in a joint venture. As part of this joint venture, a corresponding production facility is being built on the TotalEnergies site in Grandpuits (France). The ecoMotion plants, which produce biodiesel from animal fat of Categorie 1 material (in accordance with Regulation (EC) 1069/2009), will supply this production plant in Grandpuits in the future.

As the Sternberg site produces biodiesel based on vegetable oils and fats, the site will not be part of this joint venture. In order to be able to meet future challenges in the markets even better, and to benefit even more from synergies in raw material procurement, the site became part of ReFood GmbH & Co. KG on December 1, 2022. Since 2018 ReFood has been supplying the site with UCO, so combining the two companies was a logical and correct step. However, this has not changed anything about the site’s business model. As before, the rapeseed oil mill, the biodiesel plant and RVM Logistik GmbH will continue to operate at the site.

ReFood France: “door to door” strategy develops

ReFood is innovating its strategy in France by focusing its efforts on independent restaurateurs. To do this, the teams went in search of these new customers.

As reported in the previous SARIA Global Newsletter (to the article), ReFood teams set out in the west of France to meet with local restaurateurs to explore their interest in offers to collect used cooking oil and biowaste. After this first positive “field test”, it was decided to continue the door-to-door strategy with catering customers across France by having ReFood teams meet restaurant owners in the largest cities in France near the ReFood collection centers of Paris, Lyon, Toulouse, Nantes and Rennes.

To target this new customer base, ReFood France received support and best practices from ReFood’s German sales teams, who’s customer portfolio consists mainly of independent restaurateurs.

“We had the opportunity to discover ReFood’s best practices in Germany and adapt them to the French market” says Fabrice Dalla Muta, ReFood’s Managing Director and stresses that the French market is not yet fully mature in terms of bio-waste recycling, but that the mentality is moving in the right direction.

The first day of the door-to-door campaign held on 3 May was a great success by signing around twenty contracts. In addition, this campaign provides valuable information on necessary adjustments to the offers, as well as to the commercial and collection conditions. The results of this campaign will also provide information on how to implement a specific collection model throughout France. In parallel, ReFood is currently recruiting a sales force that will be specifically dedicated to canvassing these new customers.

DAKA: opens its gates

By April 2023 alone, Daka has already taken more than 250 guests on tours of its factories, and several schools have signed up for tours in the spring and summer.

The high demand has made Daka choose to make guided tours a regular workflow and make it easier for interested parties to book an appointment.

“We are overwhelmed and proud of the great interest that Daka has received in recent years. To meet the many requests, this year we have introduced that you can book guided tours directly via Daka.dk, for which we have created a tour calendar that we will continuously fill up,” says Søren Mohr Jensen, Head of Communication & Marketing at Daka.

Daka is especially popular with agricultural colleges because the company has contact with all branches of production. At the same time, Daka works a lot with the relationship with their surroundings and immediate environment. Both in relation to the impact of noise and odors from the factory, but also in relation to the products they produce – which contribute to greater recycling of residues for the benefit of the climate and the environment.

This attitude is echoed by Agricultural Colleges approach to teaching. Caring about the local environment is part of the education, and it resonates well with the values that Daka helps to promote, explains teacher Maren Kirstine Steensen Jensen.

“Our students become trained farmers, where Daka is an important part of the value chain for farmers. In addition, on a farm, you can also be inspired by the work of being accepted in the local community, how to work with energy optimization and much more,” she says.

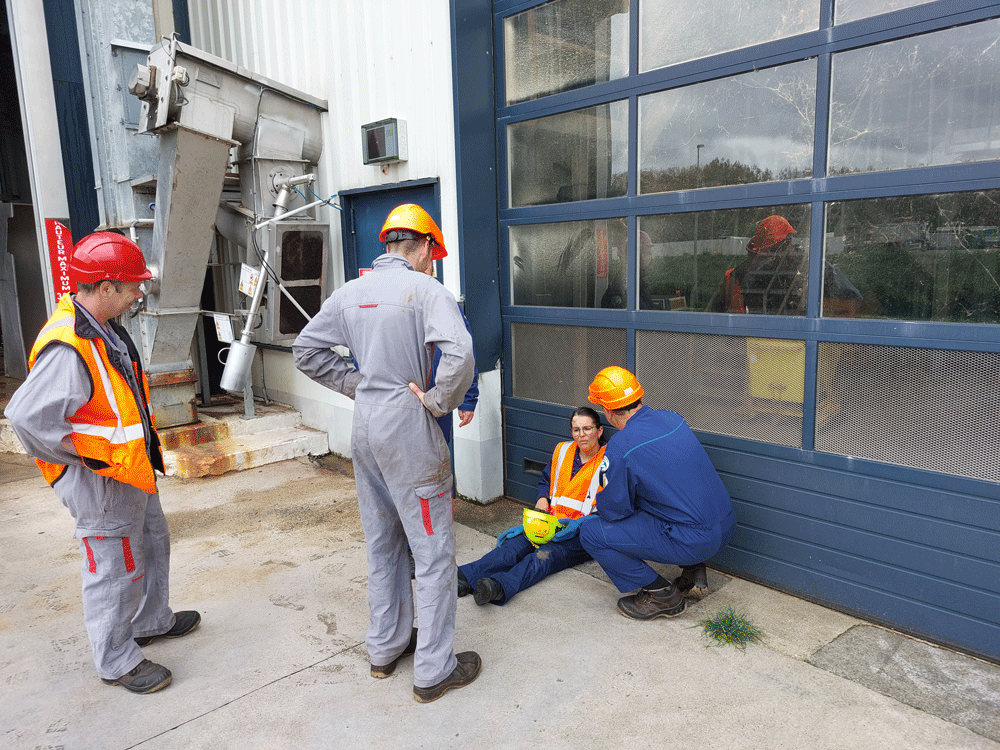

SecAnim France: raising awareness under the sign of health and safety

For the World Health and Safety Day, the SecAnim teams successfully organized events for employees to raise awareness of the risks associated with our activity.

The annual World Day for Safety and Health at Work on 28 April was an occasion for the members of the SecAnim QSE (Quality, Safety, Environment) team to mobilize the collaborators.

This year, the theme chosen was “a safe and healthy environment”. For this occasion, workshops were organized for the collectors in the centers and for all the employees in our production facilities.

For collection center employees, the activities focused on the safe handling of collection containers. An important topic as there have been around ten accidents in this context since the beginning of the year. To address the issue in a lighthearted way, participants were asked to identify dangerous situations in their daily lives, in the course of their work and when working on the farms, for example when a collection container is defective. This method is a subtle way of raising awareness.

For collection center employees, the activities focused on the safe handling of collection containers. An important topic as there have been around ten accidents in this context since the beginning of the year. To address the issue in a lighthearted way, participants were asked to identify dangerous situations in their daily lives, in the course of their work and when working on the farms, for example when a collection container is defective. This method is a subtle way of raising awareness.

As for the employees present in the plants, the workshops focused on raising awareness of the need to fully secure equipment before each use. To everyone’s great surprise, each workshop began with a fake accident in which an employee was injured because his or her work equipment was not secured prior to use. This was a good opportunity for everyone to remember first aid procedures before moving on to identify the cause of the accident.

SecAnim Poland: the website is live!

In April, the Polish SecAnim website was officially launched.

SecAnim’s operates in Poland at three production sites and four collection points. Each of the three sites operate in the market under a different name: SARIA Polska in Gołcza, Eko-Stok in Górskie Ponikły-Stok and STRUGA in Jezuicka Struga. In April, the Polish SecAnim website was officially launched.

Because SecAnim operates in a highly competitive free market, where customers decide for themselves who to place their orders with, maintaining three different brands became a challenge. With a unified offering across the country, a single brand approach and a coordinated team in administration, all sites benefit from the associated synergies and are better able to approach key accounts.

The establishment of the secanim.pl website now unifies the joint presence of the three companies online. With the external communication of SecAnim as a brand in front of the brands of the production sites, all employees can now officially identify themselves with the SecAnim family Poland in addition to their local company affiliation.

With the launch of secanim.pl, the previously operated websites EkoStok.pl and Struga.pl were closed and their visitors are now automatically redirected to the new SecAnim website. For a short time, a small logo of the old brand will be visible because of long-time customers, but the direction is simple: SecAnim is one business unit and one SecAnim family.

The Polish SecAnim website is based on the French SecAnim layout and was created by SARIA Group Communications and the Polish colleagues from Communications, Marketing & Sales. Now it is time to prepare the Spanish SecAnim website as well. Stay tuned!