Dear colleagues,

we are pleased to present the first internal SARIA Global Newsletter.

This newsletter contains information on Group-wide news to keep you up to date and to provide specific insights and background on processes and developments.

In addition, we also want to get closer together as a Group.

The aim is simple: share information + get in touch = move forward together!

Your SARIA Group Communications

SAF meets SARIA

Together with the French energy company TotalEnergies, SARIA is launching an exciting project to produce sustainable aviation fuel (SAF) from residue material like used cooking oil and fats from animal by-products. Discover the new product website on www.saria.com by clicking on the red button below.

Organics2Power combines the Group-wide activities of ReFood, SecAnim and ecoMotion in the field of sustainable energy sources based on organic raw materials. Check out the latest topics by clicking on the red button below.

The topics are: SecAnim Spain: Residuos Aragón joins the SARIA Group //

ReFood France: new organisation . . .

Sinova combines Group-wide activities in the production of high-quality primary products and ingredients for industrial customers in the animal feed, feed, aquaculture and oleochemical industries. Check out the latest trending topics regarding this division by clicking on the red button below.

The topics are: Sinova at a glance

Food & Pharma combines the Group-wide activities of Van Hessen and Bioiberica in the field of natural casings and pharmaceutical active ingredients. Check out the latest trending topics regarding this division by clicking on the red button below.

The topics are: 120 years Van Hessen: selection Then & Now //

Bioiberica consolidates its ethical corporate governance

New Director SARIA Group HR

From November 1st 2022 Claus Eckmann strengthen the SARIA Team as the new ‘Director Group HR’ for the SARIA Group. A key task will be to team up with the local and divisional HR units in order to create a resilient and powerful network that will enable SARIA as a Group to meet the strategic challenges jointly and efficiently while providing professional support for the constant process of change.

Sustainability Report & Flyer 2022

Check out the current SARIA Sustainability Report and the corresponding flyer. To achieve greater transparency for internal and external partners, it highlights various aspects of sustainability along the way SARIA does business. For this prupose the report provides initial insights regarding all divisions of the Group.

EcoVadis Medal 2022

The SARIA Group has once again been awarded the silver medal by EcoVadis. As an independent and the world’s largest provider of sustainability ratings, EcoVadis evaluates the sustainability performance of around 90,000 companies. In 2022, SARIA Group was able to further improve the performance in all four areas and is now among the top 11% in an industry comparison.

SARIA Corporate Video – new language versions

In addition to the English language version, the SARIA Corporate Video is now available in Spanish, German, French and Polish. Check out the different language versions on our YouTube channel SARIA Group.

SARIAnews 2022

Check out the the current issue of the company magazine SARIAnews 2022. It takes a look at what has moved SARIA in the past and and takes a closer look at what is to come.

SARIA UK: updates and news

SARIA UK provides information on news and developments in selected business areas. This includes rendering updates 2022 as well as information on activities regarding T. Quality – an important component of SARIA UK’s Food Services. Check out the latest trending topics regarding SARIA UK by clicking on the red button below

The topics are: SARVAL (Nottingham) // SecAnim (Widnes) // T. Quality continued expansion across the UK Food Service Market

What comes next?

You can look forward to the next SARIA Global Newsletter in the next months.

You have ideas, wishes, comments? Share them with us at: newsletter@saria.com.

SARIA Global Newsletter 01/2022

SecAnim France: call for tenders – the particularity of the market

In France, SecAnim collects animal material from livestock farmers thanks to its 22 collection points distributed throughout France and its three processing plants in Plouvara (Brittany), Bayet (Auvergne Rhône Alpes) and Benet (Pays de la Loire).

Before 2009, the rendering market was managed by the French State, which decided on the contracts to be awarded. Today, the market is private and managed by seven livestock associations (also called ATMs), which survey all renderers every three years. Farmers cannot choose the rendering service provider and are obligated to use the selected renderer. This national call, which is valid for the next three years, is therefore a crucial moment for SecAnim in France. Obviously, some areas are more strategic than others, especially in regions with many livestock farmers. The challenge is not to get the most territories, but the right ones.

In 2021, the work of the teams has allowed SecAnim to maintain its leading position in the French market against its main competitor Akiolis.

The change in BSE risk status has transformed the SecAnim market in France

In May 2022, France’s bovine spongiform encephalopathy (BSE) risk status has been recognized as negligible by the World Organization for Animal Health (OIE). In August 2022, the European Commission followed and, since then, has taken into account the new BSE status of France at the Union level.

Up until now, animal by-products of cattle from Category 1 were exclusively destined for the production of meal that can be used for energy purposes (heat, green electricity, biodiesel). This measure was introduced after the outbreak of BSE in the 1990s, which led to the exclusion from the food chain of any animal material that could pose a potential or proven risk of transmitting the disease.

Due to the absence of any new cases of BSE in France since 2016, the European Union decided to reclassify cattle aged 12 months or less as Category 2 material and move France from a so-called “controlled risk” area to a “negligible risk” area.

After the official announcement of this change, the SecAnim teams showed great responsiveness. Within 48 hours, all collection points in France were informed of this change and immediately modified the settings of their collection equipment and procedures.

From now on, the challenge is to compensate for this decrease in tonnage by controlling energy consumption and by improving recycling, especially of Category 2 materials. This will be done with the help of the R&D and sales teams as well as the sites.

SecAnim Poland: search for new contractors in neighboring country

Polish SecAnim will negotiate an agreement with Biovela Group, one of the largest Lithuanian slaughterhouses. This is an important signal for a competitive market.

The Polish SecAnim sales team works in a free market. For each customer order for the collection of animal raw material, we compete with other service providers. One of the day-to-day tasks is the constant search for raw material sources. With a keen sense, the sales teams search for new potential customers, and recently this search has expanded to neighboring countries. These efforts have already paid off, as an agreement is negotiating with the largest Lithuanian slaughterhouse, Biovela. The plan is to start weekly collection of Category 1 material, which will be transported and processed at SecAnim’s Eko-Stok plant in Poland. We are also negotiating the collection of Category 3 material to be transported and processed at the Sinova plant in Przewrotne.

“Searching for new sources of raw materials is our daily business. So, of course, we also check, what we can get from a neighboring country like Lithuania. The location of the plant where the raw materials are processed is close to the border, and transport costs are relatively low. In addition, competitors in the Polish market offer lower prices for slaughterhouse pickup, so we are looking for new markets where we can negotiate higher prices. I hope that we will sign this agreement very soon and we will find more opportunities to develop SecAnim in Lithuania”. – says Jan Kopeć, Head of the Sales Team in SecAnim Poland.

SecAnim Spain: Residuos Aragón joins the SARIA Group

On September 7, all employees of Residuos Aragón, S.L., a company recently acquired by SecAnim, were welcomed into the SARIA Group.

Residuos Aragón, a family-run traditional company, was founded in 2000 and specializes in the treatment and utilization of Category 1 and 2 “sandach” meat by-products in the Autonomous Community of Aragón, one of the regions with the largest pork production not only in Spain but also in Europe.

During the meeting in Muel (Zaragoza), where the plant is located, Miquel Vila, SecAnim Country Manager, explained to all employees the history and structure of the SARIA Group, as well as SecAnim’s future prospects on a national level.

The presentation was followed by the official welcome with a breakfast at the premises, where all those present had the opportunity to ask questions to the SecAnim managers.

The new site of Residuos Aragón is a sign of the development of the SecAnim market in Spain. As Organics2Power division, we are happy to welcome 23 new colleagues. With this strong support, and together with our customers and suppliers, we look ahead to a common path to offer maximum value as a trusted partner.

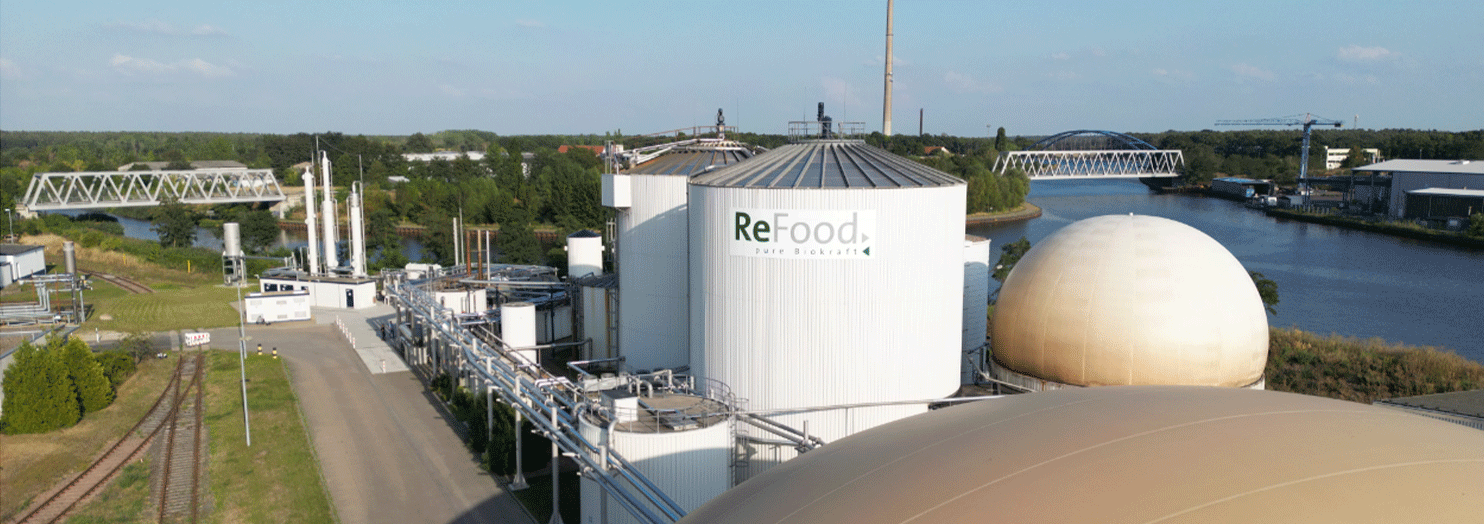

ReFood Germany: one-year anniversary of the first gas-to-grid plant

It was a long way from the idea to the final construction of the first gas-to-grid plant for ReFood Germany at the AD biogas plant in Genthin. Therefore, the local ReFood-Management is even happier that the first birthday of the new plant will be celebrated in September 2022.

In the gas-to-grid plant, the raw gas from the AD biogas plant is cleaned of its CO2 component by using physical absorption after desulfurization, so it can be supplied as biomethane to the National Grid. To purify the raw biogas, an organic absorbent (solvent) is used to selectively remove gas components such as CO2 and hydrogen sulfide. The entire plant is extremely energy efficient, as no process heat input is required, and the total energy demand is less than 0.2 kWh/mN3 raw biogas.

At maximum capacity, the plant can process 350 standard cubic meters (Nm³) of biomethane per hour and is currently running at 100 percent capacity in normal operation. For the coming years of operation, maximum capacity utilization remains the declared goal. In addition, the company plans to liquefy the extracted CO2 in the future to use it in technical applications.

The plant cost 1.9 million euros to install. In addition, there were further investment costs of 2.1 million euros for, among other things, the pile foundation of the soil to ensure its load-bearing capacity, as well as for the installation of a modern desulfurization plant and the modernization of the process system of the biogas plant.

The installation of such a plant to produce grid-quality biomethane has several advantages. As an important element of renewable energy concepts, biomethane is an essential component to secure the energy supply of the future. In addition, the sales of biomethane have developed over the years into an efficient alternative to fossil fuels and direct electricity generation via combined heat and power plants. The increasing demand for self-sufficient and above all green energy supply, but also the fact that biomethane, in contrast to energy from direct power generation, can be stored, make this type of energy supply competitive and future-proof.

For the expansion at the Genthin site, the close connection to the National Grid was the key factor for the project realization, because the costs of a price-sensitive connection were avoided. The biogas plant in Genthin is located on the extensive site of a former washing powder factory, and the new plant was smartly positioned so that a future expansion can be implemented without any problems, should a third digester for the biogas plant be planned in the future.

In the UK, ReFood also operates two gas-to-grid plants in Widnes and Dagenham. In addition to the Genthin site, the ReFood plant in Kogel (GER) is also considering the installation of a similar project.

ReFood Poland: partner of Polish Culinary Cup 2022

POLAGRA, the largest exhibition promoting food, technologies for the food industry, as well as equipment and solutions for the HoReCa sector, took place on September 26-28. ReFood approaches the gastronomy sector during the event by partnering with the Polish Culinary Cup 2022 (KPP 2022).

Our initial declaration to participate in the POLAGRA Food-HoReCa-Foodtech fair and to be a partner of KPP 2022 initially aroused surprise among the organizers. After explaining the needs of the market and ReFood’s role in food waste management and involvement in the circular economy, we were received with great satisfaction by the organizers. As a partner of KPP 2022, we had two goals. First, the promotion of sustainability solutions, circular economy, education in the field of proper food waste management, and its positive impact on the environment, climate, and business. The second goal was to promote the ReFood service and become better known among chefs and cooks as the right brand and a suitable partner for food waste management. We achieved both goals and generated interest in our business model. In addition, we made some valuable business contacts among restaurateurs and mass catering representatives.

The KPP 2022 ended with a ceremony where we, as partners, presented prizes to the three winning teams. The prizes were vouchers for the purchase of ReFood service in a catering establishment specified by the winners. We are the first company in the industry in Poland to establish contact in this way and begin to build brand awareness among one of the key target groups for our company. We plan to further promote ReFood services and sustainable solutions in the world of gastronomy not only at trade fairs, but also as a partner of congresses and meetings of chefs.

ReFood Poland: a site under construction but already a good neighbor

A new ReFood site is being built in Mszczonów, Poland. In the process, we emphasize a good relationship with the local community.

In October 2021, we started the construction of a new ReFood plant in Mszczonów near Warsaw. The completion of the production and office buildings is currently in progress. The new ReFood plant will be one of the most modern plants in the SARIA Group and one of the most modern plants in the Polish industry. The plant is scheduled to open in early 2023.

Being a good neighbor

As a socially responsible company, we want to help and support local communities wherever we have a presence. To help local authorities cope with the wave of Ukrainian refugees, we handed over 100 sets of books (Polish language manuals and a Ukrainian-Polish dictionary) to the deputy mayor of Mszczonów in the second half of May. The textbooks and dictionaries went to children studying in six elementary schools in Mszczonów commune.

ReFood Spain: strengthening the relationship with customers

Our customers are becoming more active on the Internet and have a greater influence for the purchasing decisions of others. Therefore, companies must not only convince consumers, but listen to them, care about them and build long-term relationships with them.

This is exactly what we are working on at ReFood: listening to customers and offering them our help so that they can dedicate all their time to the growth of their business. Therefore, in July, ReFood Spain launched its first email marketing campaign to inform our UCO (Used Cooking Oil) customers in the Autonomous Community of Catalonia about a change in the legislation, which they had to implement immediately so that we could continue to provide them with a daily service. To help them adapt to the new regulations, we also offered them a free ReFood service that they could request by filling out a simple form, telling us all the information they needed. In this way, we were able to ensure that we continued to offer our service while strengthening our relationship with them.

We consider this campaign a pilot project and want to develop different ways of interacting with our customers. IT solutions will play an important At ReFood, we continue to grow and are committed to a relationship with our customers and suppliers based on transparency and proximity, providing maximum value as their trusted partner.

ReFood France: new organization

Today, ReFood France is a unified organization with one mutual goal: to become the No. 1 in France in collecting food waste

The collection and treatment of oil and organic residue had been in existence for several years, but they operated separately under the names Allo à l’huile and Bionerval. In order to harmonize the practices of the SARIA Group, ReFood was created in October 2021.

The ReFood France priorities

To achieve its goal in being the preferred partner for sustainable solutions, the areas of development for ReFood France are multiple:

– Be service-oriented towards the customer and improve communication.

– Optimize the plants (collection centers and treatment stations) to bring them into line with the Group’s standards.

– Increase the valorization of the end products (biogas and digestate).

– Be more responsive to the demands of local communities.

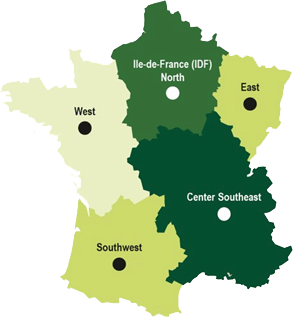

A new regional organization

At the end of 2022, ReFood in France is reorganizing its internal organization to better adapt to current specificities and locations. A regional organization has been set in place.

Each region has its own objectives and the same team organization scheme. This will allow to be more effective locally.

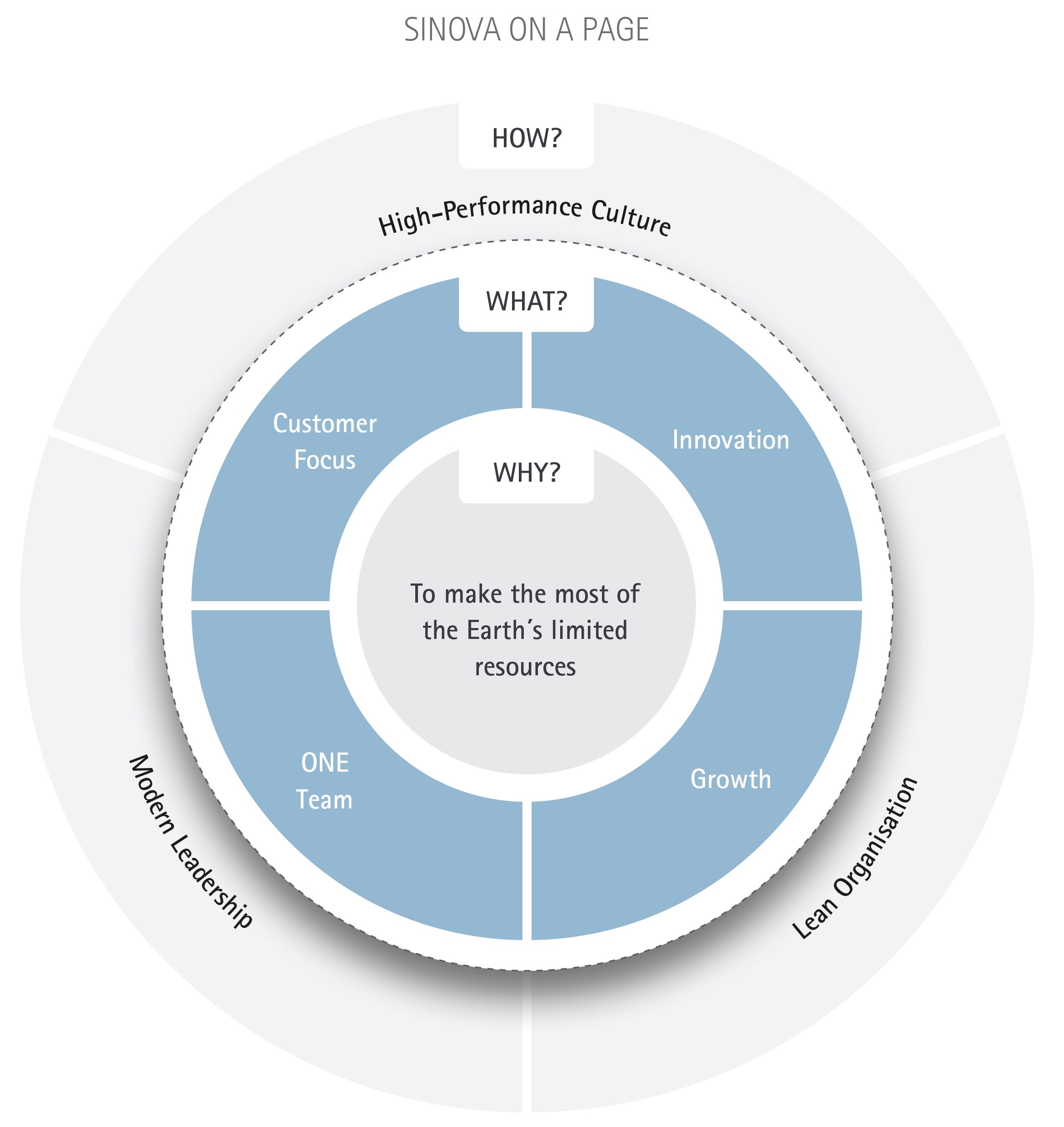

Sinova at a glance

Dear colleagues,

For the first edition of the SARIA newsletter, we would like to give you an overview of Sinova, as some SARIA colleagues are probably not yet familiar with the details of the divisions.

Sinova is one of the SARIA Group’s three operating divisions and produces high-quality primary products and ingredients for customers in the petfood, feed, aquaculture and oleochemical industries. The factories of Sinova are located in France, Spain, Italy, Romania, Poland, Russia and Belarus. In addition, the fish processing sites and the wet petfood activities in Germany, France, Spain and the Netherlands are also part of our division. Altogether 2,100 colleagues work at Sinova, with 1,600 of these working in the blue-collar sector.

Clear organizational structure

Sinova has a clear and international organizational structure at all levels and in all areas. For example, Nestle, the world’s biggest food supplier and the second biggest petfood manufacturer, is one of our major customers and very globally organized. Like Nestle, nearly all of our customers operate with an international approach. Therefore, Sinova goes across national borders to serve these customers in the best possible way. At our division, the customer will find one single point of contact for his or her needs. The same applies to operations. Of course, there are country-specific and local factors that we have to address as a division, but we are at the same time ONE Team working together in different regions and areas. In this context, Sinova is an organization that gathers different brands such as Bioceval, Kervalis, ECB, etc. as a unifying structure.

The graphic “Sinova on a page” combines all this, answering the why, the what and the how. Our target is to make the most out of earth’s limited resources. We can only achieve this by being ONE Team at Sinova, which operates in a healthy, safe and fun work environment. We want Sinova colleagues to be proud of the business they work for and engaged with the Sinova purpose and ways of working. We have a clear focus on our customers and want to be an attractive destination for talents. At Sinova the continuous drive of innovation is key for our long-term and sustainable growth. We want to achieve all of this with a modern and open leadership approach, establishing a high-performance culture that excites our colleagues and leads to a mutual team engagement in combination with a lean and agile organization.

The meaning of the name

The name Sinova reflects this approach and objectives. Sinova stands for Sustainable, Ingredients, Nutrition, Oleochemicals & VAlorisation. Furthermore, the word Sinova calls to mind a symphony or an orchestra, which only works if everyone in the team is engaged and participates. However, when this orchestra performs, harmony and cohesion are the result. Sinova also contains the word nova, which means new. New is not only the name but it also reflects the modern approach to leadership at Sinova, which encourages everyone to play an active role in our division. That is the basis for our future growth and success.

In order to express these new approaches and ideas that we are implementing at Sinova, and to ensure a unified appearance and identity of our division, we have also developed a logo. ONE harmonized and all-embracing line forms our Sinova globe. We are ONE team and ONE division that unites the principles that our colors reflect. Our business is a global one. We no longer think in national borders and live an international approach to our business and our customers. The colors that fill the globe illustrate our core values and point to our principles:

Technical Blue:

We know our business in detail and have extensive technical expertise.

Sustainable Green:

We make the most out of Earth‘s limited resources.

Communicative Purple:

We are the preferred partner for our customers and listen to their needs.

Down-to-earth Grey:

We are down-to-earth, open-minded and proud of what we do.

On this basis, together with the Group Communications team, we developed a Sinova corporate design, with a harmonized signature, a Sinova slide master and many other useful tools. Compiled in a brand book, these tools will now be made accessible to all Sinova colleagues and further developed in the coming weeks and months.

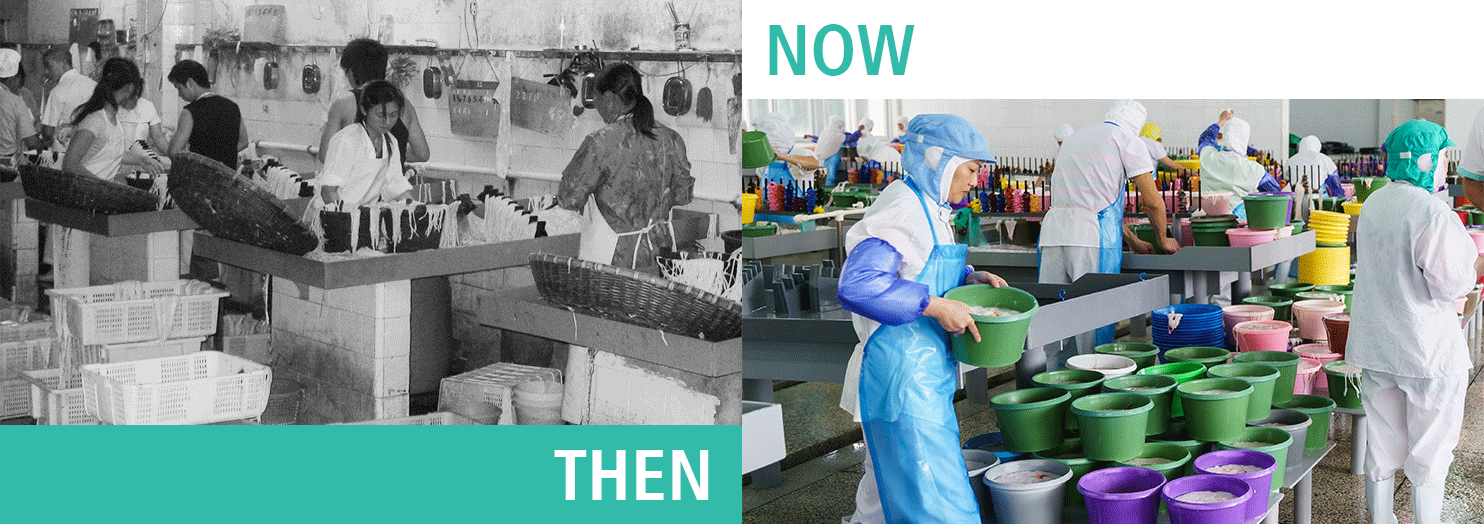

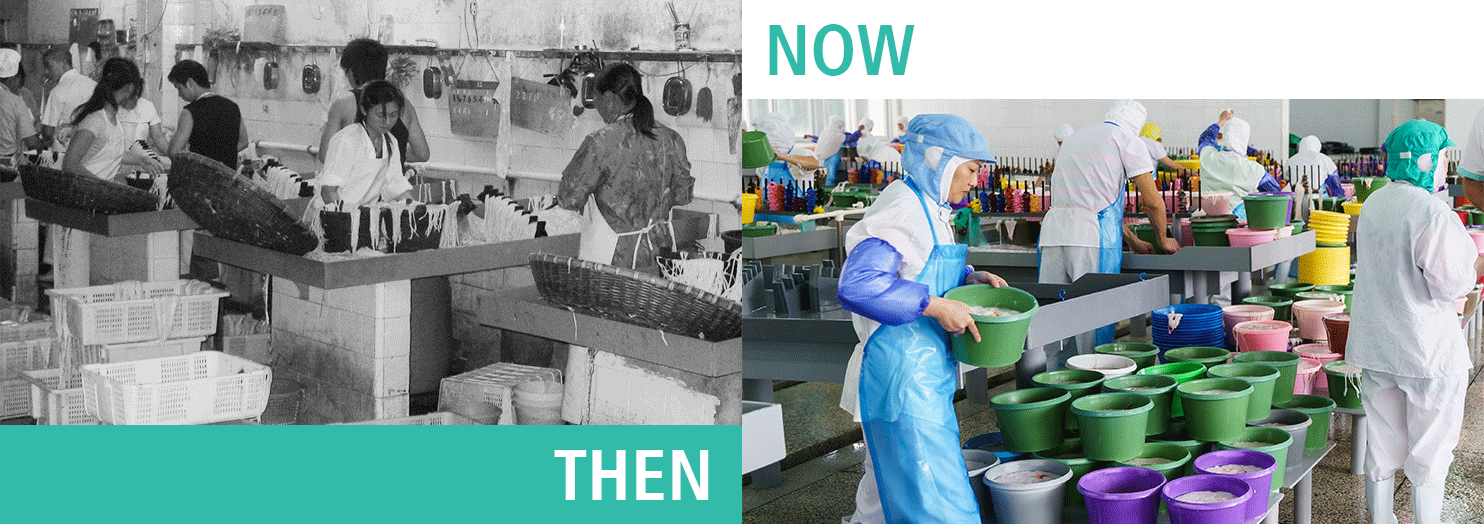

120 years Van Hessen: selection Then & Now

Van Hessen is 120 years old! A true milestone! During a time that companies come and go and changes on the world stage follow one another in rapid succession, it is comforting to see that some things have a more permanent character. Van Hessen is here to stay!

Click here for the timeline as pdf.

Van Hessen uses an extensive selection process to deliver natural casings of consistently high quality. What was it like then and what is it like now?

THEN Selection of natural casings was a different game in the past. Production methods, working conditions, and production output all vastly differed from today. Just 20 years ago, only 5 to 10 calibers were produced, and all were neatly bundled according to the 16-2 specification. Calibers refer to standardized casing diameters, while the 16-2 specification required a hank to comprise no more than 16 pieces that could each be no shorter than 2 meters. All products left the factory in dry salt rather than brine, which came later. And when brine was finally used, the workers had to make it themselves. Working conditions were also far from ideal. There was no air conditioning in the summer. What is worse, workers had to use cold water to rinse casings during winter in a factory without heating. There were few safety standards at the time and workers did not have to wear the special clothing required today.

NOW Today, people wear special white outfits and they no longer work with their hands in ice cold water. Regardless of whether the plant in China orders a truck with boiling water or transports steam from the factory across the street to its facility, numb hands belong to the past. Besides better working conditions, the big difference is that the simplicity of the past has made way for complexity. Even though people work everywhere according to the same standards (a clear improvement), the range of calibers has expanded. We now select for twice as many calibers as before. The 16-2 standard for bundles has been replaced by an assortment of specifications and packaging: nets, tubes, and plastic bags. We now have a line-up of 60 different products. At the same time, our flexibility has increased. Orders constantly change and customers often ask for adjustments. This agility is required, as Van Hessen becomes an increasingly global company.

Bioiberica consolidates its ethical corporate governance

This endorses the company’s commitment and responsibility to strengthen and consolidate its ethical corporate governance based on the strictest legal and regulatory standards.

Bioiberica, a global Life Science company committed to improving the health and well-being of people, animals and plants, has announced the certification of its Criminal Compliance Management System following an audit carried out by Bureau Veritas. Bioiberica obtained this certification in March 2022 after a huge amount of work led by its compliance team.

Criminal compliance consists of processes, controls and tools that ensure greater control and surveillance in preventing criminal risk within an organisation, thereby avoiding potential sanctions and/or convictions. That’s why Bureau Veritas is committed to using this standard since it enables Criminal Compliance Management Systems to be implemented that not only respect Spanish legal requirements but are also aimed at meeting the expectations placed on organisations operating in international markets, as is the case of Bioiberica, present in over 80 countries.

The audit was carried out by Bureau Veritas, becoming the first organisation to be accredited by Spain’s National Accreditation Body (ENAC) for UNE 19601 certification of Criminal Compliance Management Systems. The audit process verifies whether the standardised management model has been correctly implemented and developing a customised management system for Bioiberica that meets the standard’s requirements has been a challenge for the Bureau Veritas. Nevertheless, Bioiberica’s willingness and commitment have increased awareness of the importance of such systems regarding the responsibility of organisations. The company operates within an extremely regulated sector and has always complied with the legal requirements of public authorities, which has helped to assess the criminal risks related to its activity and to further strengthen the controls already in place.

Bioiberica has been committed to certifying its systems and processes with Bureau Veritas for more than 7 years. It already has a Management System in accordance with ISO 9000 and ISO14001 certification, as well as certification for its CSR Management based on the SDGs, EMAS III environmental certification, 45001 for Occupational Health & Safety and 50001 for Energy Efficiency, among others.

According to Jordi Vidal, CFO and Compliance Officer of Bioiberica, “this certification recognises the hard work carried out by the entire compliance team, which in turn has required the involvement and dedication of the whole company. Our main aim has been to develop and foster a culture of compliance, in line with the strictest ethical and regulatory standards that govern our business. We’re proud of this recognition, which undoubtedly encourages us to continue working and striving to improve and expand our Compliance Management System”.

For Teresa Rodon, Commercial Director and CSR and Environment Manager at Bureau Veritas Spain and Portugal, “the certification of our Criminal Compliance Management System demonstrates Bioiberica’s commitment to complying with applicable legislation, industry codes, internal standards and rules of good corporate governance, as well as consolidating the ethical and performance culture throughout the organisation, enhancing the company’s positioning as a successful, sustainable organisation”.

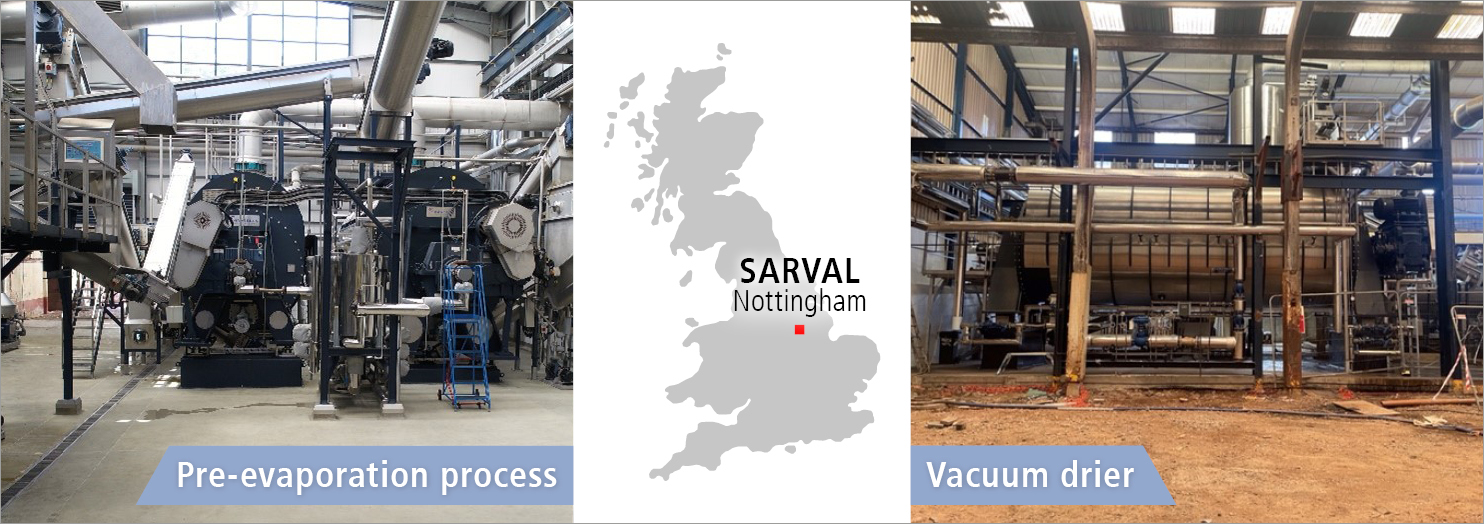

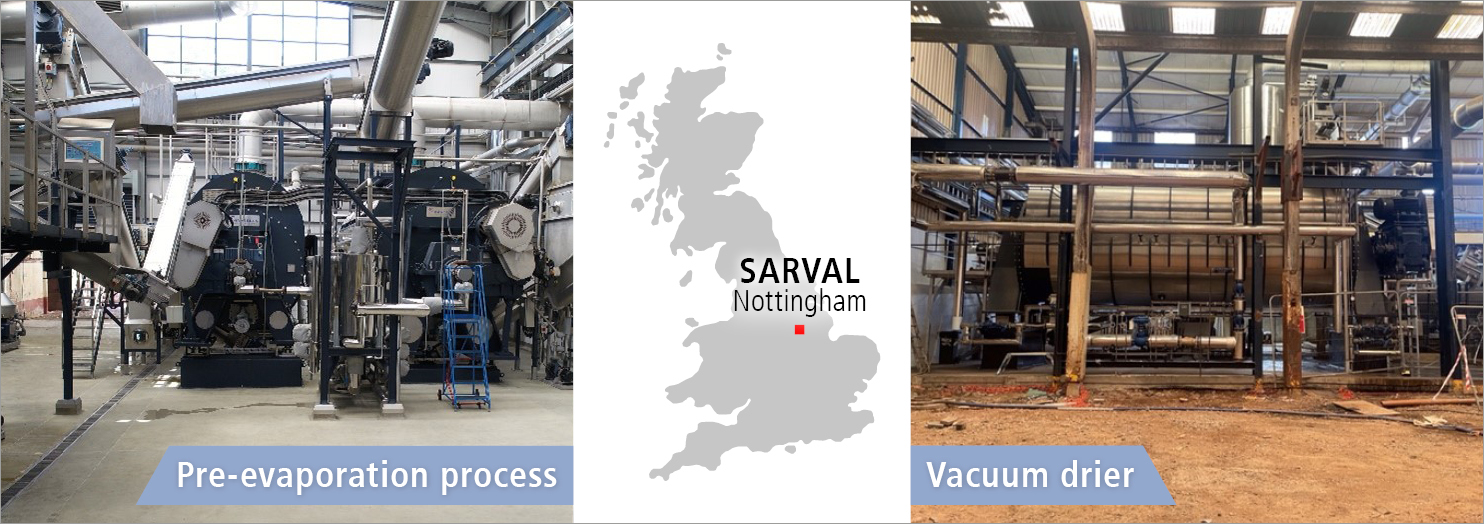

SARVAL (Nottingham)

The SARVAL in Nottingham informs about current developments.

Vacuum Drier: In October 2022, Sarval Nottingham is due to commission a new 480m2 rotor disc drier on it’s feather processing line. The new drier will be capable of operating under vacuum, a first for rotor disc driers in the UK. The new drier provides redundancy and increased capacity alongside enhancing the final feather meal. The new drier can operate as the second machine in series or independently. By drying the material under vacuum, the final discharge temperature can be lower (70-80°C), which should increase the digestibility of the final product, improving its saleability and value. The new drier forms part of a wider investment strategy in the site as whole.

Pre-Evaporation Process: As part of a global strategy to reduce its energy consumption and Carbon footprint, Sarval is investing in a new Waste Heat De-Watering (WHD) process for its poultry processing line in Nottingham. The initial investment includes a rotor disc pre-heater, twin-screw press and 2-phase shell and tube heat exchanger. The new equipment will be located within an extension to the renovated building from 2017. The investment will enable a proportion of the water to be evaporated from the raw material without the need for steam heating by utilising waste heat from the existing driers. Up to 18T/h of raw material can be pre-heated, and separated into two phases, a solid

phase, and a liquid phase. The liquid phase is concentrated using the heat exchanger before re-joining the existing process to produce poultry fat and poultry PAP. The investment will reduce the Saria UK’s CO2 emissions by 5,000 tonnes per year. Finally, the throughput of the poultry process using just the single drier, will be increased to 27 T/h. This new process is due to be commissioned in July 2023.

SecAnim (Widnes)

Category 2 Processing Line: SecAnim Widnes is diversifying its processing portfolio through the investment in a new dedicated production line for category 2 raw materials.

This new process will produce a category 2 meal fit for use as a Nitrogen boosting fertiliser, in addition to uplifting the value of the Tallow from that of category 1 to that of category 3. The process itself includes a new raw material hopper within the new raw material facility, two stage size reduction prior to batch cooking the material to sterilise to Method 1 conditions. The sterilised material is then separated via a tri-canter into a solid phase which is dried, via a newly installed 400m2 machine, to produce the final category 2 meal. The meal will then be cooled and ground/screened in advance of final sales. The tri-canter also provides the finished fat product and a liquid phase which will be used as a biomass fuel within the bubbling fluidised bed facility onsite. This makes the process totally unique to SecAnim Widnes and allows for the reduction in energy consumption of the ‘rendering’ whilst maximising the value of new products. The category 2 fertiliser product will complement SecAnim’s existing KalFos fertiliser sales. The new process is due to come online in April 2023.

T. Quality continued expansion across the UK Food Service Market

2022 has seen T. Quality further strengthen its position as the UK’s leading fish and chip shop and fast-food wholesaler with its expansion into two new sites based in Hillington (Glasgow) and Fareham (Portsmouth).

Delivering a variety of products ranging from fish and chip shop supplies, fast food outlets and pizza supplies through to wholesale fish. T. Quality had previously operated a fully integrated national service network across 10 sites in the following locations Bristol, Birmingham, Bovey Tracey, Bridlington, Darlington, Leeds, Peterborough, Staplehurst, Swansea and Swindon. The expansion sees T.Quality grow to 12 active depots across the whole of the UK.

The two new sites have also started their waste oil collection service as part of T.Quality’s planned growth in the used cooking oil sector.

T. Quality – Portsmouth

Set in the Fort Wallington Industrial Estate, T. Quality – Portsmouth opened in April 2022 into a 16,000 sq.ft pre-existing site. Located minutes away from the M27 the site opens fantastic network and routing opportunities across the south of England.

The new site created 16 jobs and is currently operating with six trucks, two express vans, and one used cooking oil collection van.

The site will offer deliveries from Pool to Seaford including the Isle of Wight.

T. Quality – Glasgow

Set in Hilington Park, Scotland’s largest business park, T. Quality – Glasgow opened in August 2022 into a purpose-built unit following the acquisition of Morrisons Foodservices in March 2022. 25,000 sq.ft in size the T. Quality Glasgow branch is the largest to date.

The site created 25 new jobs for the local area and is currently in full operation with 10 vans and 1 lorry in use with further investment planned for the delivery fleet into 2023.

The site will offer deliveries to the whole of Scotland.

Mike Crees, Managing Director of T.Quality said: “The expansion into both our new Portsmouth and Glasgow depots are really exciting opportunities for T.Quality as a whole. Both sites will add further capacity to our operation but will also help to enhance customer service levels with increased delivery dates and the opportunity to reach new areas.

Portsmouth will see us continue to grow on our already exceptional reputation on the south coast of England. The site allows us to offer a better and more focused service to our existing and new customers and will expand delivery options to key holiday areas in the south of England. The Portsmouth site will also help in reducing our carbon footprint out of our Swindon and Staplehurst sites.”

Mike Crees continued “The acquisition of Morrisons Foodservices based in Glasgow allowed T. Quality to significantly build on a growing customer base in Scotland. The purpose-built site is the largest of all our depots and shows the exciting potential and plans which we will be laying down in Scotland and is truly a game changer for how we will operate in the region.”