SARIA Global Newsletter February 2023

O2P France, Poland, Spain: Proposing solutions by listening to employee needs

Well-informed employees, who feel comfortable in their work environment are not only more motivated at work, but also contribute to a positive working atmosphere that benefits everyone.

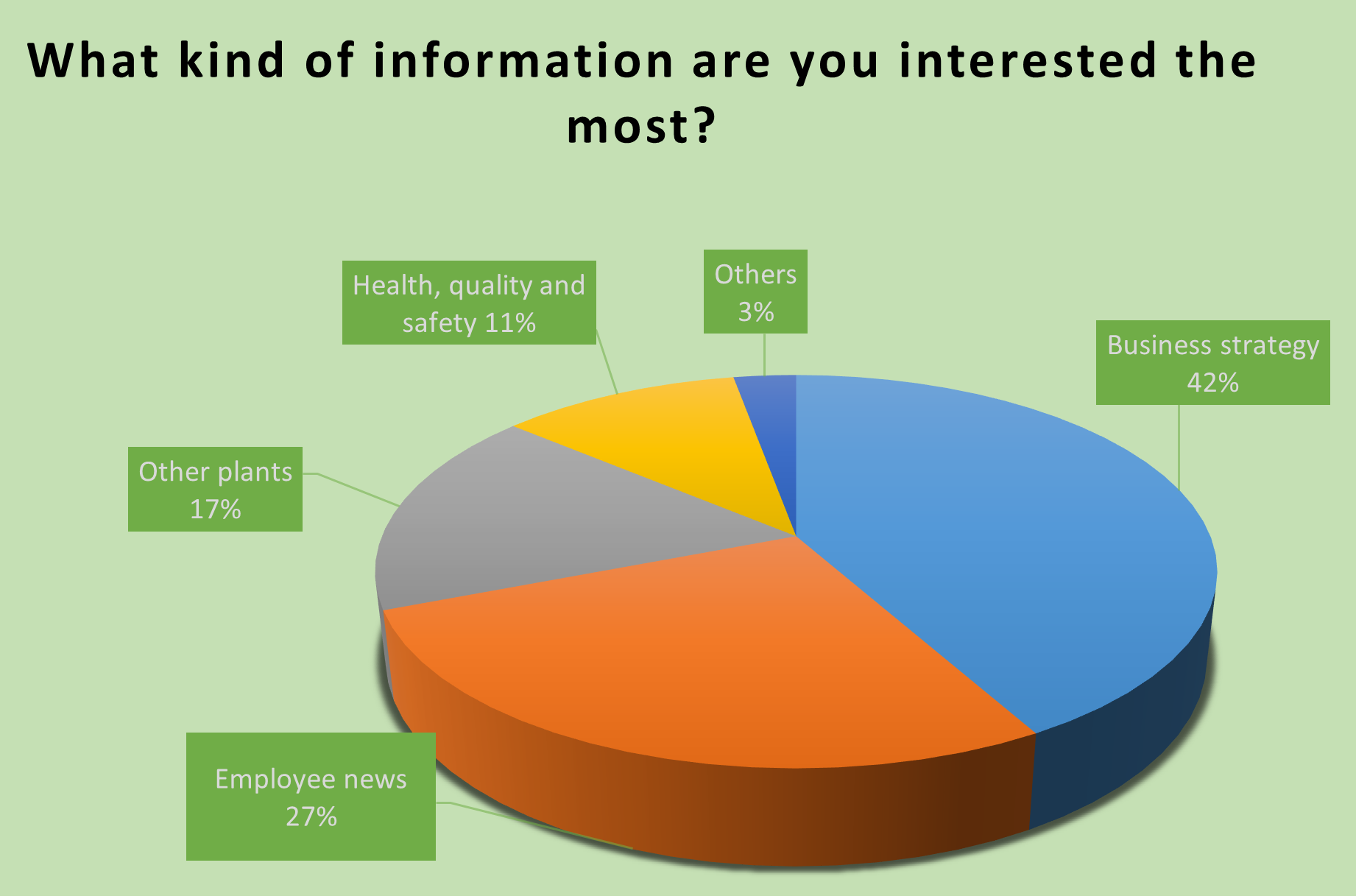

In terms of communication habits and needs, the O2P communication team in Spain, France and Poland conducted an initial employee survey within the O2P division in these three countries. Based on the results, they can now develop tailored solutions to meet employees’ expectations.

Process

In November 2022, the O2P communication team conducted an employee survey. Via e-mails in the respective local language and by using posters with QR codes at the sites, all employees of the O2P business units in Spain, France, and Poland as well as colleagues from the administrative functions in these countries like HR or Finance were surveyed. The questionnaire included, for example, questions on “How do you feel informed?”, “Where do you look for company information?”, “How often and in what format would you like to receive information?” etc.

Results

The response rate among colleagues with access to the computer was 31 %. There was little feedback, 8 % of all responses, from production colleagues and drivers, who were able to participate in the survey via the QR code. O2P employees feel well informed, with an average score of 3.13 out of a possible 5 (5=excellent informed). Respondents want more information about their sites’ business prospects and news from other plants and colleagues to improve these results.  In addition, many respondents wanted more contact and exchange with their direct supervisors, as well as more internal channels, such as an intranet, for exchanges among themselves.

In addition, many respondents wanted more contact and exchange with their direct supervisors, as well as more internal channels, such as an intranet, for exchanges among themselves.

What’s next?

The O2P communication team will provide detailed evaluations of the survey to the business unit management in every country. Together, a plan will be created to improve internal communication and establish a flow of information between local management and employees. At the end of the year, the survey will be repeated to check whether the communication strategies initiated are having an effect. It is essential that we maintain the dialog we have started on internal communications so that we can continue to develop collectively in this area.

COP27 | Sustainability Challenges & Opportunities at O2P by 2023

COP27 is the annual meeting of signatories to the United Nations Framework Convention on Climate Change to review progress in implementing the agreement.

On the occasion of this climate conference, the O2P division in France, Poland and Spain has examined its own challenges and opportunities in the area of sustainability and identified key facts for itself.

Because everything that happens at COP27 affects us as a company.

These key facts to challenges & opportunities can be found here.

If you want to know more about sustainability in O2P read the full interview with Claudia Gutiérrez, Sustainability Assistant & Project Manager for Roberto Pérez, O2P’s Sustainability Director.

Daka SecAnim: Support of Danish customers with app update

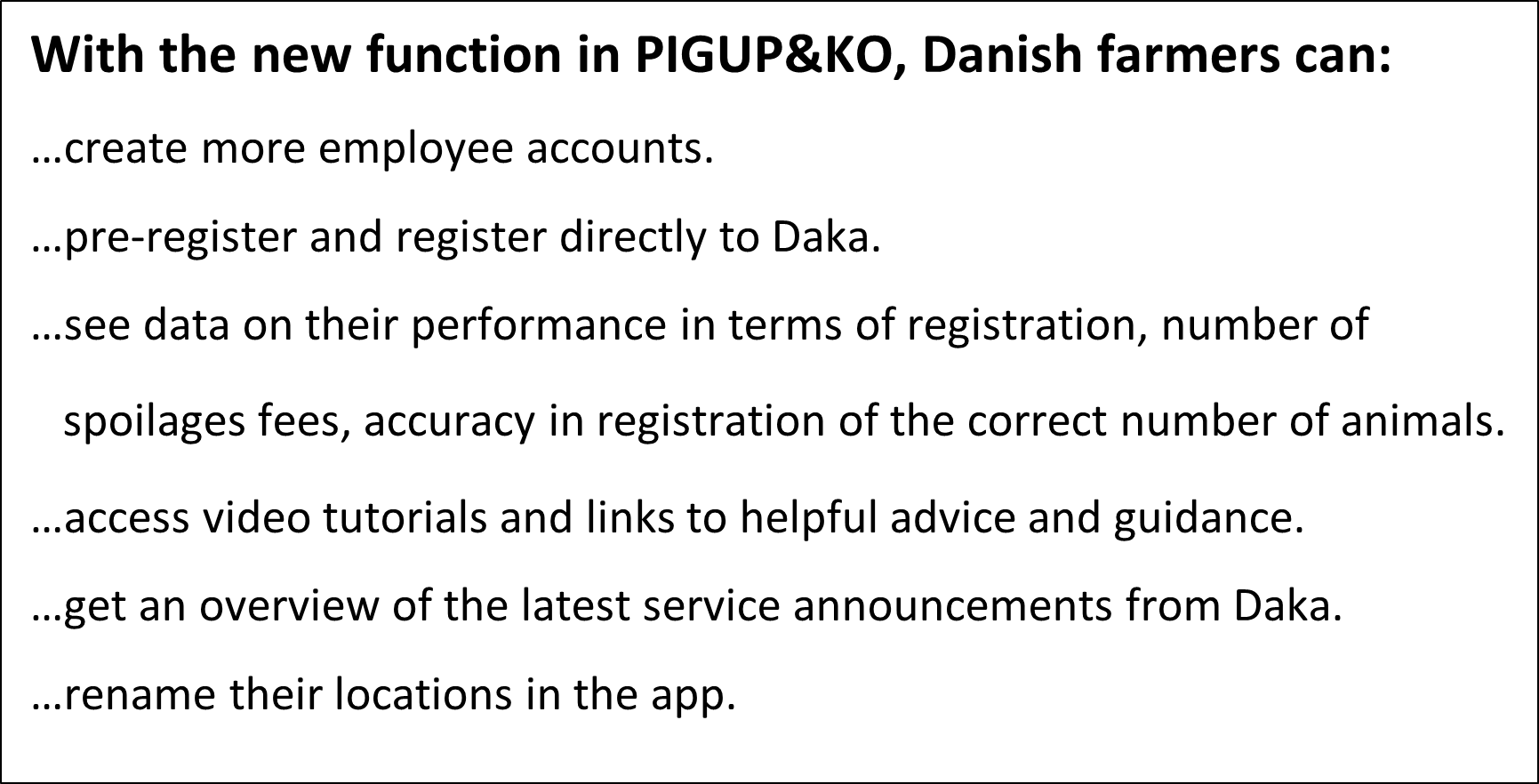

At Daka SecAnim in Denmark, they experience great success with the new update of their app named “PIGUP&KO”. With several new functions, the app will make it easier for Danish farmers to manage fallen animals in their day-to-day business.

The Danish Daka SecAnim collects fallen animals, primarily from Danish farms and private animal husbandry, which are recycled for fertilizer production, biofuel, and biodiesel.

In order to minimize the possible spread of infectious diseases, fully comply with legal requirements and simultaneously save time in day-to-day business, fixed routines are needed with regard to the removal and registration of fallen animals.

In 2015, Daka SecAnim launched the app “PIGUP&KO” for the Danish farmers. “Back then, the main purpose was to make it easier for farmers to register their fallen animals for collection. In this way, they could register directly from their smartphones, and they did not have to use a PC or touch-tone telephone. Here the ambition was to achieve better service, faster collection and at the same time protect security”, Søren Mohr Jensen, Communications & Marketing Manager at Daka SecAnim says.

“Our route planning is dynamic, meaning that our truck drivers receive an updated route every five minutes. When farmers register fallen animals for collection through the app, they might “risk” that we collect the animals five minutes after registration. The app has supported our dynamic route planning right from the beginning”, Søren Mohr Jensen explains. Daka SecAnim’s dynamic route planning ensures that 20% of the animals can be picked up on the same day they are registered in the app.

Service and safety are still in focus

Service and safety are still in focus

After seven years, the PIGUP&KO app was ready for a major update in the fall of 2022. To make the app as easy and smooth as possible for farmers, PIGUP&KO has the same basic functions as before, but with some new features. Among the new functions, it is now possible to create different users (employee accounts) directly in the app, and at the same time control whether employees can “only” pre-register or directly register a collection appointment with Daka SecAnim. This means that an employee who brings fallen animals outside the stables can pre-register them. The authorized person, who has the permission to register the collection from Daka SecAnim, will be informed that a fallen animal has been found. When the animal is placed at the collection point, the authorized person can forward the registration to Daka SecAnim, which will pick up the animal as soon as possible.

At the same time, it is also possible for the farmer to benchmark themselves against other Danish farmers in terms of registration and delay, as well as registration of the correct number of fallen animals.

“We are looking forward to help the Danish farmers to even more effective and streamlined handling of fallen animals. It will take time, but once they get started, the handling of the animals will be much easier for them”, Søren Mohr Jensen concludes.

SecAnim Poland: New investment in Struga Jezuicka

At the end of 2022, a new investment was completed at the SecAnim site in Struga Jezuicka.

The investment included:

- the construction of a new raw material reception hall with the installation of production machinery

- the construction of a new deodorization installation, which includes a water-chemical scrubber and an installation of a new biofilter.

The plant is now pending acceptance by the authorities in order to start production.

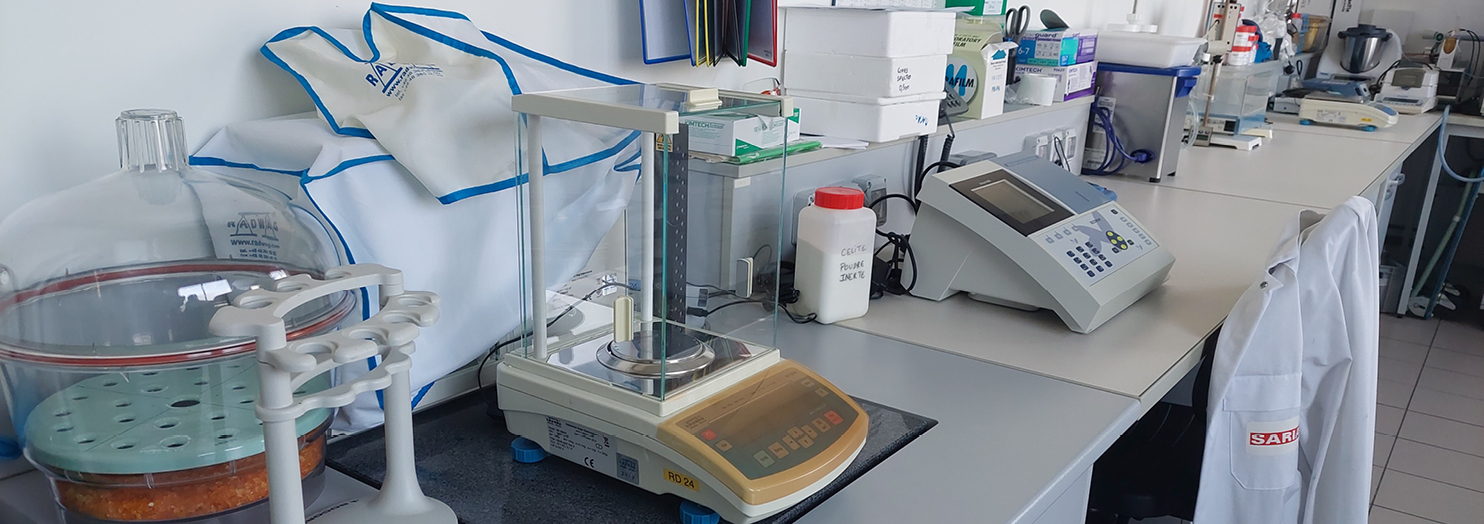

photos: a new raw material reception hall

photos: a water-chemical scrubber

SecAnim Spain: Sponsor of the IV Edition of the Porc d’Or Awards

With the participation of more than 800 professionals, including farmers, veterinarians, representatives of public administrations, associations, universities and companies, the Porc d’Or awards have become the benchmark event for the pork sector in Spain. This time SecAnim was one of the sponsors of this event.

On November 25, the IV Edition of the Porc d’Or Capa Blanca Awards was held in Toledo (Spain), an award promoted by the Instituto de Investigación y Tecnología Agroalimentarias (IRTA), to recognize excellence in the Spanish pork sector.

Our company was represented by Eduardo Puigvert, Sales & Purchasing Manager of SecAnim and Laura López, Executive Assistant & Project Manager. Both presented the Porc d’Or Award for “Health, Animal Welfare and Environment”.

These awards were created with the clear objective of rewarding the professionalism, dedication, and work done daily by pig farms in Spain to ensure the future of the sector. Values that are completely in line with SecAnim’s philosophy and commitment to all Spanish farmers.

Sponsoring the Porc d’Or Awards is a very good way to showcase our company and clearly communicate our sustainable values to key stakeholders in the industry.

SecAnim France: Maximizing the valorization of materials

In France, the teams of Research & Development and SecAnim aim to develop a new end product – a biostimulant for plants. It will be produced from residual materials as part of a project to valorize condensates.

Condensates are water residues produced and condensed during the transformation process of materials in SecAnim’s plants. Currently, these residues are sent to our wastewater treatment plants for disposal. Biostimulants are usually supplements based on microorganisms or bioactive substances that improve plant growth and stress tolerance.

Within the Innovation Department, Valérie Mezino and Hélène Protopopoff are leading this project together with ReFood’s fertilizer project manager Dylan Collet and other expert colleagues in France, Spain, and Poland.

This research began in the summer of 2022 with a bibliographic review to find previous studies on the subject. Valerie and her team then identified the types of condensates in the Plouvara and Benet plants and their potential “collection points”. Not an easy task in the context of our complex infrastructure! The collected material has been sent to an external laboratory to analyze its composition. The next step will be to conduct tests to examine the biostimulatory effect of the condensates. This work will require several trials to obtain conclusive results. We expect the first results by the end of winter 2023.

For Valérie: “this project reflects the sustainability of our Group. Although we already work very sustainable, valuable materials are still getting lost in our recycling activities. In this case, it is about creating materials to produce organic fertilizers.”

This approach is part of a more global project called “Side Streams Valorization”, which is exploring the valorization of unused streams like condensate, sludge, and other residues or waste from rendering plants. This global project brings together the O2P division in France, Spain, and Poland to share the results of the various research projects and to analyze the side streams in terms of their profitability and usability.

ReFood Poland: New Director for Sales and Market Development

At the beginning of 2023, Piotr Kosinski joined ReFood Poland as Sales and Market Development Director.

Piotr has been working in the industry for more than 13 years.

Over the past years, he has managed nationwide sales developing cooperation with retail chains and industrial plants in the field of comprehensive waste management. At ReFood, he will manage the sales department and be responsible for ReFood’s sales and market development strategy, with a focus on business development in the UCO area.

ReFood Poland: New plant in Mszczonów

In the last issue of the SARIA Global Newsletter, we reported about the construction of the new ReFood plant in Mszczonów near Warsaw.

Construction work on the production and office buildings has been completed. The last work to be done is the asphalting of the parking lot and the roads located on the site.

At the moment, almost all the machinery in the “basement” has been installed. The unpacking unit for the collected waste is also already in place.

By the end of January, the installation of the pressure washer system as well as the turntables and control cabinets will begin, thus allowing us to start connecting the power and control lines. The commissioning of the waste processing line is planned for the end of March.

We expect the authorities to examine the construction by the end of February. Once the relevant waste permits have been issued, the plant will probably be fully operational by the end of the third quarter of 2023.

ReFood France: Learnings from a fire at the Etampes plant

On the night of Saturday, November 19, 2022, the fire alarm was activated in the reception hall of the Etampes plant.

The plant manager on site quickly realized that the smoke was coming from the general electrical panel room. He contacted emergency services and then activated the plant’s emergency shutdown.

Expert’s report

The expert’s report concluded that an unexplained short circuit in an electrical panel, which was in compliance with standards and had been checked, was the cause of the fire in the reception area.

Although the fire was quickly brought under control, the smoke, humidity and powder discharged by the fire brigade destroyed the entire electrical room.

Severe consequences

The fire resulted in a 13-week shutdown of the anaerobic digestion plant and a significant loss of operations. During the shutdown period, the site had to be restored to its original state by draining all the pipes, cleaning the digester and restoring it, and then carrying out preventive maintenance on all the equipment. The interruption of operations and the reconstruction are covered by insurance.

Assessment of the situation after the fire

First of all, the Etampes teams worked together in a strong spirit of solidarity that enabled them to continue collecting waste in spite of the deteriorated conditions. Each week, 700 tonnes of bio-waste were sent to external service providers. The working conditions were also difficult for the operators and the people in the offices without heating or electricity during this period. However, the site’s projects did not stop. Solidarity was also expressed within the group with valuable legal assistance from the very first hours of the fire and the participation of the Technical Department in finding the electrical parts needed to rebuild a switchboard.

Learnings from this event

- Regulatory compliance is essential to ensure that insurance companies are able to cover high amounts

- Critical equipment must be secured as soon as possible in the event of a power cut

- Frequent thermal camera inspections of electrical cabinets, frequent cleaning of electrical cabinets by professionals with tightening of the lugs and an automatic extinguishing system using inert gas in the switchboards would have limited the impact of the fire.

ReFood France: Change in legislation opens new markets

French legislation changed in January 2023. From now on, all producers of more than 5 tons of biowaste per year (previously 10 tons) must have a solution for recycling their biowaste.

By December 31, 2023 at the latest, this obligation will apply to all producers or holders of biowaste, including local authorities in the framework of the public waste management service and private and public establishments that generate biowaste.

This new obligation opens new markets for ReFood, which tested a “commando” operation in the streets of Niort at the beginning of January. The objective is to develop our presence in the catering market, for which we currently collect mainly used edible oils.

After a quick training on how to present ReFood and the commercial offer, a team of 15 employees from the Trade, Industry and Logistics departments went to meet the city’s restaurant owners.

In total, more than 80 restaurants were visited during one day of canvassing. 25 were interested in an offer for oil collection, four for organic material only, and 24 for a double collection. One contract was signed immediately, while 53 customers asked for a commercial proposal.

Given the success of this day, this type of operation will be repeated in various French cities with awareness-raising campaigns for our current customers.

At the same time, a whole strategy will be developed to approach the local authorities, which are not very advanced in this field.