SARIA Global Newsletter November 2022

SARVAL (Nottingham)

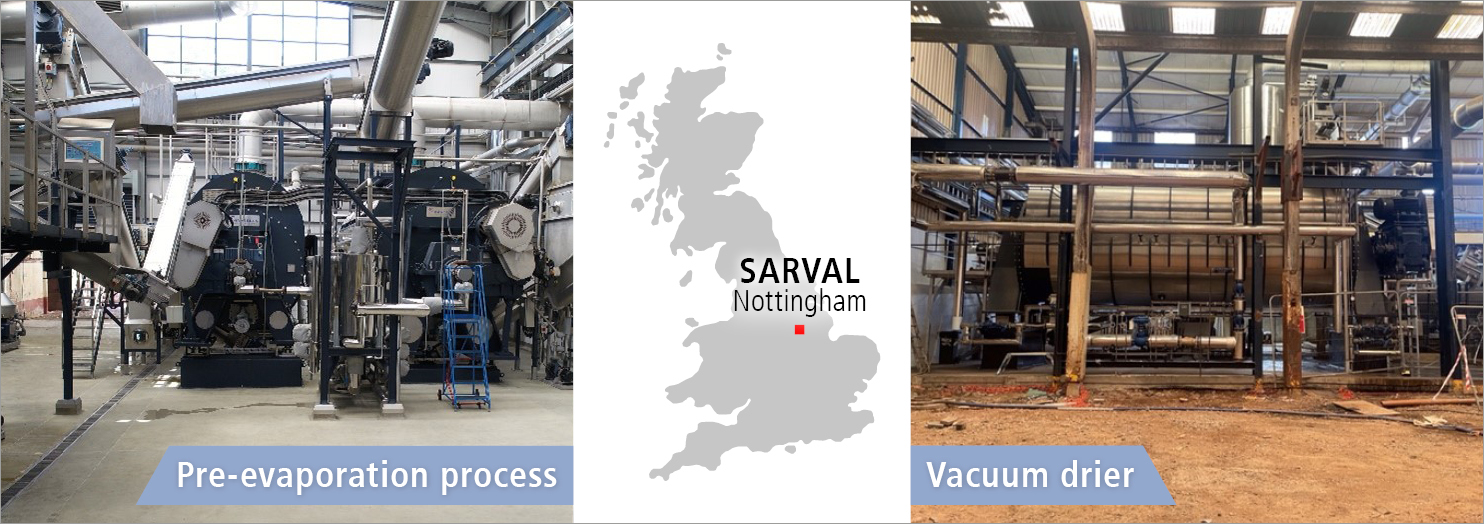

The SARVAL in Nottingham informs about current developments.

Vacuum Drier: In October 2022, Sarval Nottingham is due to commission a new 480m2 rotor disc drier on it’s feather processing line. The new drier will be capable of operating under vacuum, a first for rotor disc driers in the UK. The new drier provides redundancy and increased capacity alongside enhancing the final feather meal. The new drier can operate as the second machine in series or independently. By drying the material under vacuum, the final discharge temperature can be lower (70-80°C), which should increase the digestibility of the final product, improving its saleability and value. The new drier forms part of a wider investment strategy in the site as whole.

Pre-Evaporation Process: As part of a global strategy to reduce its energy consumption and Carbon footprint, Sarval is investing in a new Waste Heat De-Watering (WHD) process for its poultry processing line in Nottingham. The initial investment includes a rotor disc pre-heater, twin-screw press and 2-phase shell and tube heat exchanger. The new equipment will be located within an extension to the renovated building from 2017. The investment will enable a proportion of the water to be evaporated from the raw material without the need for steam heating by utilising waste heat from the existing driers. Up to 18T/h of raw material can be pre-heated, and separated into two phases, a solid

phase, and a liquid phase. The liquid phase is concentrated using the heat exchanger before re-joining the existing process to produce poultry fat and poultry PAP. The investment will reduce the Saria UK’s CO2 emissions by 5,000 tonnes per year. Finally, the throughput of the poultry process using just the single drier, will be increased to 27 T/h. This new process is due to be commissioned in July 2023.

SecAnim (Widnes)

Category 2 Processing Line: SecAnim Widnes is diversifying its processing portfolio through the investment in a new dedicated production line for category 2 raw materials.

This new process will produce a category 2 meal fit for use as a Nitrogen boosting fertiliser, in addition to uplifting the value of the Tallow from that of category 1 to that of category 3. The process itself includes a new raw material hopper within the new raw material facility, two stage size reduction prior to batch cooking the material to sterilise to Method 1 conditions. The sterilised material is then separated via a tri-canter into a solid phase which is dried, via a newly installed 400m2 machine, to produce the final category 2 meal. The meal will then be cooled and ground/screened in advance of final sales. The tri-canter also provides the finished fat product and a liquid phase which will be used as a biomass fuel within the bubbling fluidised bed facility onsite. This makes the process totally unique to SecAnim Widnes and allows for the reduction in energy consumption of the ‘rendering’ whilst maximising the value of new products. The category 2 fertiliser product will complement SecAnim’s existing KalFos fertiliser sales. The new process is due to come online in April 2023.

T. Quality continued expansion across the UK Food Service Market

2022 has seen T. Quality further strengthen its position as the UK’s leading fish and chip shop and fast-food wholesaler with its expansion into two new sites based in Hillington (Glasgow) and Fareham (Portsmouth).

Delivering a variety of products ranging from fish and chip shop supplies, fast food outlets and pizza supplies through to wholesale fish. T. Quality had previously operated a fully integrated national service network across 10 sites in the following locations Bristol, Birmingham, Bovey Tracey, Bridlington, Darlington, Leeds, Peterborough, Staplehurst, Swansea and Swindon. The expansion sees T.Quality grow to 12 active depots across the whole of the UK.

The two new sites have also started their waste oil collection service as part of T.Quality’s planned growth in the used cooking oil sector.

T. Quality – Portsmouth

Set in the Fort Wallington Industrial Estate, T. Quality – Portsmouth opened in April 2022 into a 16,000 sq.ft pre-existing site. Located minutes away from the M27 the site opens fantastic network and routing opportunities across the south of England.

The new site created 16 jobs and is currently operating with six trucks, two express vans, and one used cooking oil collection van.

The site will offer deliveries from Pool to Seaford including the Isle of Wight.

T. Quality – Glasgow

Set in Hilington Park, Scotland’s largest business park, T. Quality – Glasgow opened in August 2022 into a purpose-built unit following the acquisition of Morrisons Foodservices in March 2022. 25,000 sq.ft in size the T. Quality Glasgow branch is the largest to date.

The site created 25 new jobs for the local area and is currently in full operation with 10 vans and 1 lorry in use with further investment planned for the delivery fleet into 2023.

The site will offer deliveries to the whole of Scotland.

Mike Crees, Managing Director of T.Quality said: “The expansion into both our new Portsmouth and Glasgow depots are really exciting opportunities for T.Quality as a whole. Both sites will add further capacity to our operation but will also help to enhance customer service levels with increased delivery dates and the opportunity to reach new areas.

Portsmouth will see us continue to grow on our already exceptional reputation on the south coast of England. The site allows us to offer a better and more focused service to our existing and new customers and will expand delivery options to key holiday areas in the south of England. The Portsmouth site will also help in reducing our carbon footprint out of our Swindon and Staplehurst sites.”

Mike Crees continued “The acquisition of Morrisons Foodservices based in Glasgow allowed T. Quality to significantly build on a growing customer base in Scotland. The purpose-built site is the largest of all our depots and shows the exciting potential and plans which we will be laying down in Scotland and is truly a game changer for how we will operate in the region.”